Aircraft industry - Turbine blades manufacturing

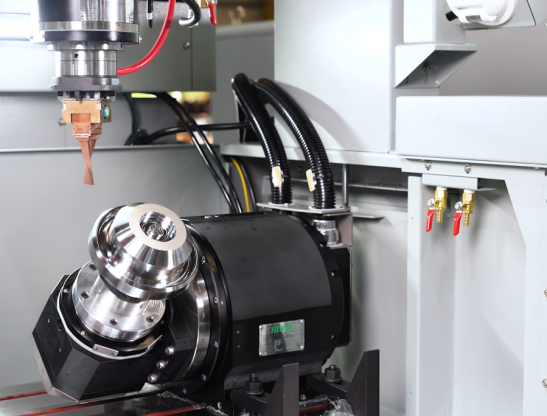

1. Innovative Value: Integrating torque motor, RCH-100E with precise indexing 0.0005° & high rotation speed 300 rpm, 3 times higher than mechanical type, with15 times improvement & continuous operation advantage.

2. Process Technology: Traditional EDM’s electrode runs vertical movement to remove material. RCH-100E’s "EDM milling", increasing 5 times efficiency & 2 um accuracy.

3. Smart Diagnostic: Integrated leakage, temperature sensor systems with "intelligent detection" to provide conditions feedback & enable users planned maintenance.

4. Energy-saving and Carbon Reduction: Utilize special aluminum alloy to reduce 30% weight with same rigidity. EDM milling technology reduces copper electrodes consumption by 70%. Reduce production costs.

Aircraft industry

A HIWIN customer from the aircraft industry manufacturing turbine blades faced challenges in increasing productivity. By using the Revolutionary EDM Technology from HIWIN, productivity increased by 5 times, electrode consumption was reduced by 70% and maintenance can be scheduled easily.

1. RCH-100E is equipped with a high-speed torque motor and can continuously rotate at 300rpm. The rotation speed is increased by 15 times compared with a mechanical rotary table with only 20rpm.

2. With 300rpm, it can be used as the spindle in EDM. With our RCH-100E, we have achieved a whole new EDM process-EDM milling. This revolutionary technology is also the first innovation in Taiwan. Through EDM milling, only one process is required to complete the machining, greatly reducing the machining time, and also reducing the use of the electrode.

3. Through the new process, electrode consumption is evenly distributed, resulting in improving the finishing quality with a surface roughness within Ra 0.4 microns.

4. RCH-100E also has an exclusive central flushing function where a 50bar water pressure effectively flushes away the EDM residue.

5. With HIWIN integrated sensors and smart drive, it can feedback information to the user, allowing the user to predict and schedule maintenance. Thereby reducing downtime and maintenance costs.

6. Our RCH-100E is made from a special alloy material that is 30% lighter compared to competing products, about 90% of the parts in this product are self-made, 70% of its parts can be recycled and used.