Company introduction中文: https://www.airaurora.tw/ 英文: https://applasma.com.tw/

Business item(s)

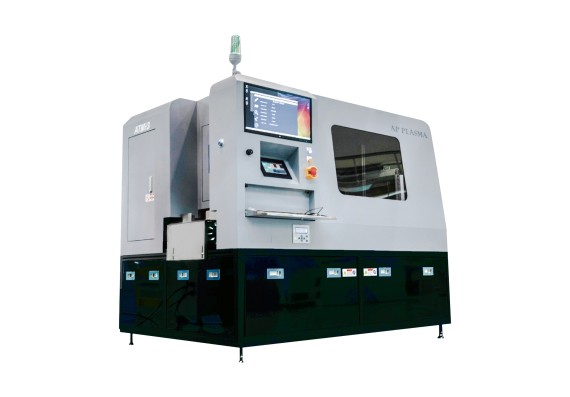

3D Air Aurora Machine (Model: ATM3)

SIZE/ 1860mm*1320mm*2150mm PRODUCT FEATURES/ (1)Energy Consumption: 5 kilowatts, certified by CE! (2)Easy-to-operate human-machine interface (3)Fully automated system, average processing speed for each shoe surface is 10 seconds (4)World-Leading High-Concentration, Low-Temperature Aurora Plasma Generator (5)Built-in automatic detection and debugging system, ensuring 100% production yield (6)Exclusive development of a 3D visual scanning system, calculating the aurora spray path for different shoe types APPLICATION FIELD: The traditional shoe-making process requires preliminary treatment such as roughing, acid-alkaline washing, and processing agents to facilitate the subsequent gluing process of the shoe surface. However, these pre-processes expose laborers to a large amount of dust, generate wastewater pollution and air pollution. Research reports indicate that the volatile solvents (processing agents) needed in the bonding process of traditional shoe-making for the shoe surface, midsole, and outsole, are one of the main causes of haze. Leaders of all internationally renowned shoe brands have also begun to require manufacturers to address the environmental external costs generated in the shoe-making process. Hence, considering these two breakthroughs needed in the current shoe manufacturing process, environmentally friendly and automated production equipment is an indispensable aspect in future shoe manufacturing. The purpose of Atmospheric Plasma Corporation’s development of the 3D Air Aurora Machine is to replace the two-stage process of roughing and pre-treatment in shoe manufacturing. Utilizing our exclusive 3D visual scanning system, we calculate the optimal plasma treatment path for different shoe types. Coupled with an automatic detection and debugging system, incomplete plasma treatment on the shoe upper can be effectively addressed. Compared to the traditional roughing process, the shoe upper treated with plasma forms stronger chemical covalent bonds with the adhesive, enhancing the bonding strength between different materials. Additionally, with the integration of the automation system, the average processing speed for one shoe upper is 10 seconds, significantly increasing the production rate compared to manual roughing. Furthermore, this automation process mitigates dust pollution issues associated with traditional roughing.