TwinCAT 3 NC I for robot-based polishing and grinding machines

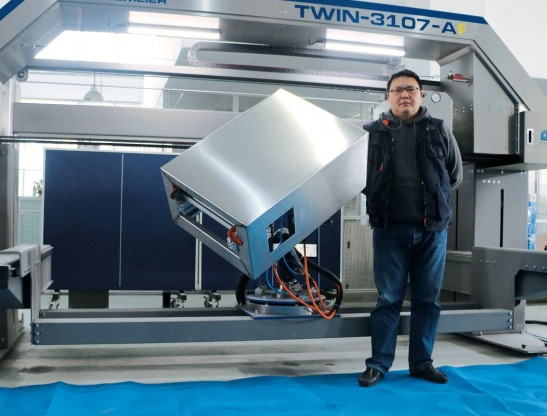

PMA Pacific is committed to replacing traditional manual grinding processes in the Chinese sheet metal industry with cutting-edge solutions. The company’s vision involves promoting environmentally-friendly and efficient automated polishing solutions and providing more customized sheet metal grinding solutions. This goal lent itself to abrasive belt grinding machines from Peitzmeier Maschinenbau, which incorporate the entire Beckhoff range of PC and EtherCAT-based control and drive technology – especially TwinCAT 3 NC I software.

PMA Pacific Machinery Company Limited (PMA Pacific)

PMA Pacific already uses PC-based control in its conventional machines. Now TwinCAT automation software will also be used for the programming, teaching and operation of newly developed robot-based polishing and grinding machines. PMA Pacific General Manager Yue Yang Zhu explains: "PC-based control technology from Beckhoff is flexible and enables convenient programming of even complex algorithms. TwinCAT offers an extensive range of functions to meet the general requirements of polishing and grinding machines. PC-based control and TwinCAT especially offer excellent real-time performance and can therefore also achieve complex motion control. The comprehensive Beckhoff product portfolio includes all the required automation components, from EtherCAT I/Os to servo drive technology through to complete control systems." The automation system of the new abrasive belt grinding machines consists of a high-performance CX2020 Embedded PC and a CP2915 multi-touch Control Panel, as well as the powerful AX8000 multi-axis servo system and AM8000 servomotors. In addition, TwinSAFE components have been integrated into the complete system to ensure optimum machine safety.

天津豐昱菱控機電設備有限公司

TwinCAT Machine Learning 助力實現產品包裝品質的智慧化檢測

中國一家大型泡麵製造商為了減少帶有包裝瑕疵的產品流入市場,降低其客戶對包裝瑕疵的投訴率,決定使用包括 TwinCAT 機器學習產品在內的倍福控制技術,使其泡麵外包裝品質可以得到即時可靠的智慧化檢測。

使用倍福的 EL1xxx 或 EL3xxx EtherCAT 數位量和類比量輸入端子模組結合 TwinCAT Scope View 採集感測器資料。然後使用開源的學習框架 Scikit-learn 訓練機器學習模型,並生成模型描述檔。控制系統中的 TwinCAT Condition Monitoring可以預處理感測器資料。然後再轉換成BML 檔,最後將該檔部署到一台 CX51xx 嵌入式控制器上運行,借助 TwinCAT Machine Learning Runtime 對即時蒐集的資料進行推理,然後將推理結果經過 EL2xxx 系列 EtherCAT 輸出量端子模組,即時剔除瑕疵品。據天津豐昱介紹,倍福控制技術具備系統開放性優勢,可以非常輕鬆地與生產線上現有的協力廠商主控系統整合 。