Company introductionhttps://www.tongtai.com.tw/tw/

Business item(s)

CT-350 5-axis Machining Center

The high performance vertical 5-axis machining center, CT-350, is able to process complicated precision parts machining for industries. These include: aerospace, automotive, biomedical, electronics, and mold industries. In addition, the CT-350 is effective for reducing set-up times and improving efficiency. 1. X/Y/Z axis travel:400/510/510 mm 2. X/Y/Z axis rapid traverse:36/36/30 m/min 3. Tool shank:BBT-40 4. Table size: 350mm ,Max loading capacity:200kg 5. Standard 15,000 direct driver type oil -air lubrication spindle 6. Standard roller cam type A/C axis

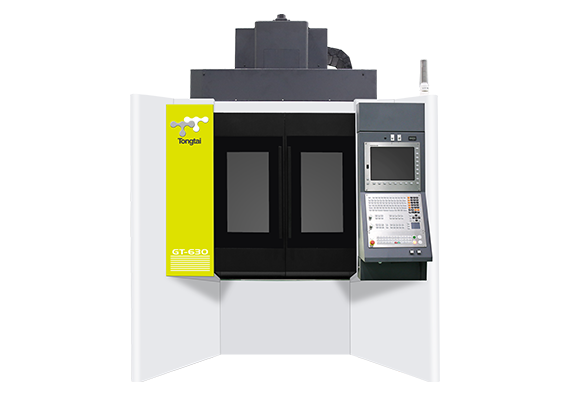

GT-630 5-axis Machining Center

GT Series is developed for aerospace, mold, and automotive parts machining. Gantry type structure, the control of three linear axes, which are free from affect of workpiece weight, and the driven centers of three axes are all on these gravity center. It significantly improves dynamic stability. 1. X/Y/Z axis travel :760/820/560 mm 2. X/Y/Z axis rapid traverse:48/48/48 m/min 3. Tool Shank:BBT-40 4. Table size :630mm ;Max loading capacity:600kg 5. Standard 15,000 rpm built-in type spindle,Option : 20,000 RPM, 24,000 RPM 6. Standard A/C axis table with DD motor

TMV-1050QII Vertical Machining Center

The rapid traverse is up to 48 m/min and the rapid automatic tool changer shortens the T to T time less than 2 seconds. These features will provide the best investment return to the customers. Excellent C type mechanical structure design provides high machine rigidity. It also assures excellent positioning accuracy during high speed and precision machining. 1. X/Y/Z axis travel: 1,050/600/530 mm;X/Y/Z axis rapid traverse:48/48/48 m/min 2. Table size (L×W) 1,100 x 600 mm ;Max. table load 800kg 3. Standard 8,000rpm belt type spindle,option 10,000 rpm, 15,000 rpm direct drive type spindle 4. Tool shank: BT-40

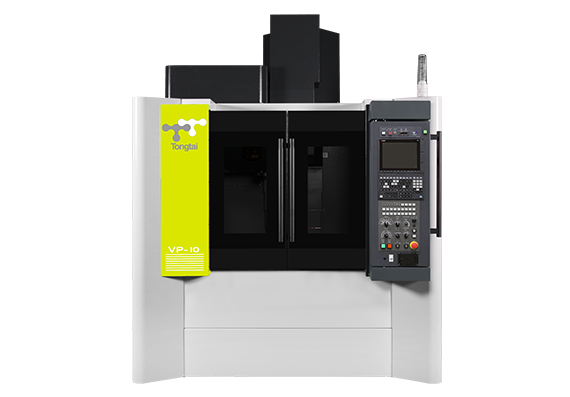

VP Series Vertical Machining Center

Direct-drive spindle with dual-contact system provides excellent machining quality and efficiency. High quality spindle and high rigidity structure design subject to high standards of machine accuracy to achieve good cutting performance. 1. VP-8 X/Y/Z axis travel 820/510/535 mm;X/Y/Z axis rapid traverse 48/48/36 m/min 2. VP-10 X/Y/Z axis travel 1,020/510/600 mm; X/Y/Z axis rapid traverse 36/36/36 m/min 3. VP-8 (VP-10) Table size (L×W): 900 (1,070) x 510 mm ;Max. loading capacity 500kg 4. Standard 10,000 rpm (option 15,000 rpm )direct drive type spindle , the tool shank is BBT-40.

TD-2000Y(BC) Multi-tasking Turning Center

TD-2000Y(BC) adopts a 75 degree slant bed design It is lowers the machine’s gravity center for enhancing the entire structure rigidity and also adopts a symmetrically saddle design, the X/Y/Z axis are perpendicular to each other with a real linear Y axis. It allows servo compensation on each axis to optimize the positioning accuracy. The sub-spindle is also available for more complex machining process, it helps to reduce labor costs and increase floor utility. 1. TD-2000Y(BC) X/Y/Z/B axis travel 230/+-51/600 / (630) mm 2. TD-2000Y(BC) X/Y/Z/B axis rapid traverse 30/15/30/ (30) m/min 3. Max. swing diameter:ø 700 mm ;The different power turret has different turning diameter. 4. Standard power turret is BMT-65, option : BMT-55 , VDI-30 (40)