Business item(s)

VACUUM DISTILLATION UNIT- HD SERIES

Wastewater that is generated through industrial production processes are a constant source of harm to the environment. Consequently, in the industrial field, it is an important environmental challenge to find methods to recycle the wastewater or to reduce the cost of wastewater treatment. Through many years of technical skill developed from our heat pump compressors along with the application of vacuum distillation theories, Fusheng successfully developed a high-efficiency and low-energy "Vaccum Distillation Unit" to implement the standards of the ISO14001 and ISO50001 management system. Vacuum distillation is the process of separating solutions by heating and evaporating different components into vapor at different temperatures, and then condensing them back into separate liquids. With the excellent heating capacity of Fusheng’s heat pump, it can obtain three to five times more heat with one unit of power, allowing the equipment to perform the vacuum distillation process with less power consumption. The HD series unit at the Fusheng Sanchong factory has been running for over a year now. Its energy-saving and wastewater-reduction outcome has been extremely obvious. On average, for every 20 barrels of wastewater that are treated, only one barrel of waste is extracted. The remaining 19 barrels of water can be recycled back for reuse in the manufacturing equipment. This effectively replaces the traditional combustion method, minimizing any concerns about air pollution.

Oil-free Screw Blower

【Low noise, highly reliable】 A unique air intake duct, as well as a reasonable configuration, ensures the suction air density, and continuous & stable operation without pressure fluctuation that has a noise level far lower than that of the Roots blower. 【Higher transmission efficiency】 Direct coupling between the motor and the blower can almost obtain 100% transmission efficiency. 【Frequency-variable model blower saves more energy】 The integration of a high-efficiency permanent magnet motor and the high-precision frequency inverter has a linearly stable operation and constant pressure control without a large starting current that makes substantial energy saving available. 【Excellent control system】 Easy to operate & control, large screen display plus intelligent control, which is as convenient as operating a palmtop. 【Lightweight, concise unit assembly】 Comparatively compact structure, lightweight, less vulnerable parts, and more economical maintenance.

Variable Frequency Screw Vacuum Pump -VSV Series

【Permanent magnet variable frequency saves more energy】 The integration of a high-efficiency permanent magnet motor and the high-precision frequency inverter has a linearly stable operation and constant pressure control without a large starting current that makes substantial energy saving available. 【Easy to use and maintain】 Simple structure that meets the premise for small-size & lightweight, and provides adequate maintenance space. 【Higher transmissio n efficiency】 Direct driving between the motor and the pump can almost obtain 100% transmission efficiency. 【Low noise and high reliability】 The system operates continuously and steadily without pressure fluctuation. The design of the whole pump unit follows the principles of low noise, high reliability, high efficiency, and energy saving. 【Independent cooling air duct】 A relatively cold airflow can be sucked from outside to go through the independent electronically-controlled heat dissipation system, independent cooler air duct, and independent motor cooling air duct that ensures the cooling effect and the reliable operation of the respective system.

oil free scroll air compressor - GW Series

The Fusheng GW series combined with advanced industrial technology, 100% oil free, with high efficiency IE3 motor and low noise vibration operation, provide high quality oil free compressed air solution. Due to its precise and planned design, the Fusheng GW scroll series has the most ideal floor space, can be placed in limited interior space and workplaces, and the exhaust range is from 0.44 ~ 1.76 m3 / min. The operating pressure was 7/8/10 bar. low power of 5-20HP, which can realize low maintenance and operation cost.

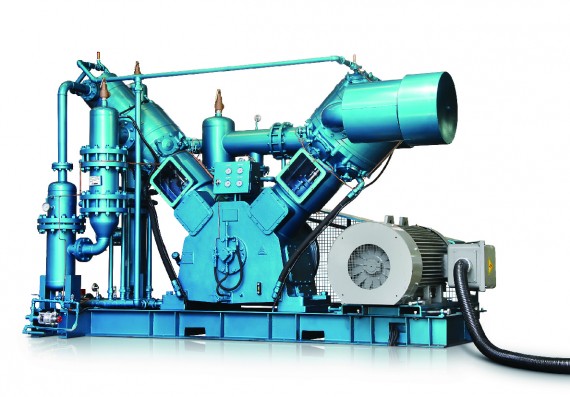

oil free reciprocating compressor-VFW Series

The Fusheng VFW oil-free, high-pressure, 100% clean air compressor series is specially designed for the PET blow molding industry. Drawing from the wealth of experience gained from long-term operations in varying conditions, the compressors are engineered to be highly efficient and reliable as they provide a stable supply of compressed air for blow molding. The series ranges from 50 to 300HP with discharge pressures ranging from 25 to 40 kg/cm2 and is accommodated for variable injection volumes. The VFW series has a built-in user-friendly interface, touch-screen panel, and PLC control system. The compressor is equipped with multiple alert systems and safety features for better overall control. Operating parameters, status, and servicing instructions are shown on the monitor to provide the user with important data concerning periodic and preventive maintenance.