Company introductionhttps://www.render.com.tw/

Business item(s)

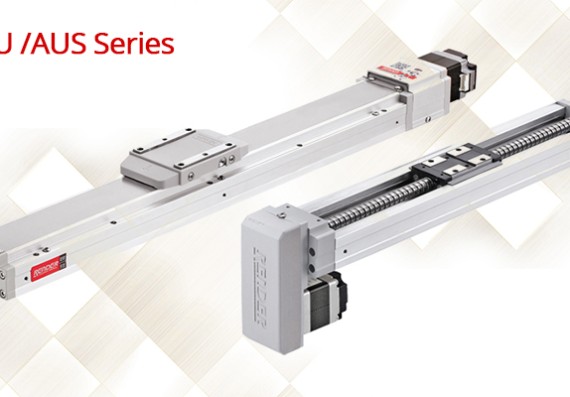

Electric Built-in Guideway Servo Actuator

RENDER Built-in Guideway Servo Actuator from the AU single-axis robot series are innovatively developed products. The linear guide and the ball screw are integrated into a U-shaped design, improving structural rigidity, reducing assembly tolerances, and greatly reducing the volume.

Electric Cylinder/Electric Micro Putter

The JDRM Series electric micro putter are ball screws driven, providing customers with two types of precision selection applications to realize high transmission accuracy.

Electric Micro Stage

Electric micro stages use cross-roller guide rails for micro-drive positioning. There are two materials of medium carbon steel and aluminum alloy for users to choose from.

Hollow Rotating Platform

Easily combine with any servo motor and stepping motor. Position at any position, the transmission gear is ground, and the repeat precision can reach five arc minutes. With high load capacity, heavy objects can be positioned directly on the platform.