Company introductionwww.anderson.com.tw

Business item(s)

MAXXIS-2931IP

The MAXXIS Series Moving Table 5-axis machining centers set a new level of 5-axis accuracy and machining performance. The combination of a highly rigid base, precision gearbox and high accuracy Servo System makes the MAXXIS an ideal choice for machining solid wood、 plastics、 aluminum and composite materials. The Anderson fixed bridge and moving table design provides easy machine access in a compact easy-to-access design. The webbed steel substructure remains smooth and rigid while all 5-axis are in full 5-axis machining mode. The MAXXIS 5-axis machining centers set a new standard in high speed 5-axis machining.

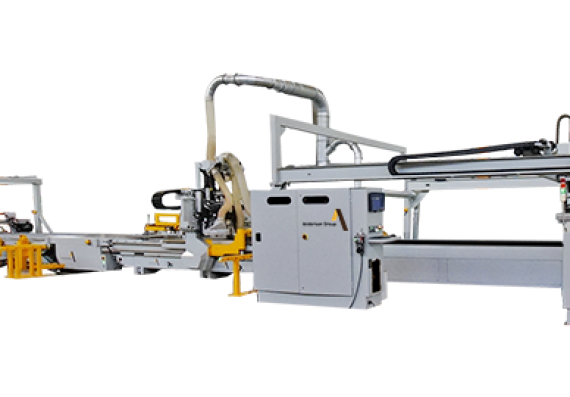

Smart Nesting Automated Solution Integrated with new design automatic storage system

The smart mechanized nesting production line developed to this solution includes a smart system to assist the production line to reduce operational manpower and reduce the risk of downtime with advance warning. Production Automation: The central control system receives a CNC file to perform the automatic loading of wood board materials and then generate control output directly. Upon loading and labeling of wood board materials, the system starts the continuous machining of wood board materials without any operator's intervention during the process, so no human errors would occur. Cyber Wood Cloud System: The stand-alone machine collects information and integrates it into the central control system, and then uploads it to the cloud to allow customers to speed up their judgments of the stand-alone machine's operation status, providing reliable information for administrators, operators, or customer service staff to judge. Overhead Crane Loading and Inspection Technologies: The unloading system optimizes its material pick-up path and generates the wood board pick-up/put-down data for the unloading process by means of a nesting software developed by Anderson, wherein its unloading module is equipped with multiple sets of suction cups, which are automatically activated by the system according to a wood board material’s size and shape to pick up/put down said material. Moreover, the unloading process can not only be stacked directly on roll pallets, but can also be optionally transferred to a subsequent process or to external equipment.